My background:

Retired, but still only 62 years old.

Qualified Engineering Drawing Teacher, Mechanical Engineer, Mechanical Designer, IT Developer. Started in drawing office 1978, started with CAD 1981.

CAD Packages used: Intergraph IGDS, Bentley MicroSystems, Matra DataVision (Euclid), SolidWorks, IBM Catia, FreeCAD. AutoCAD in 1987, briefly - hated it!

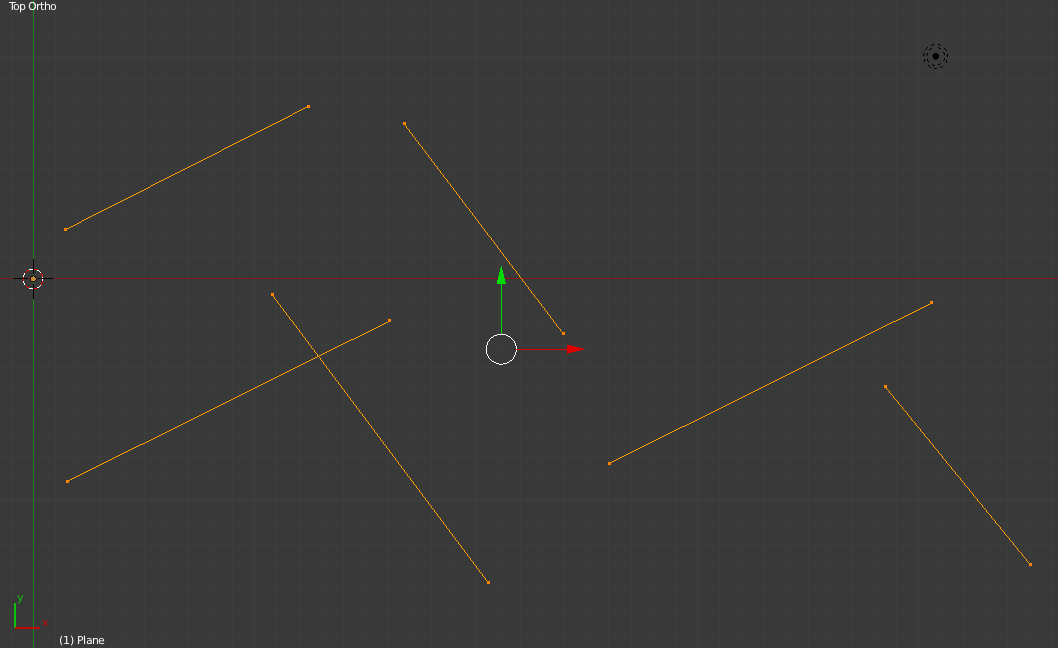

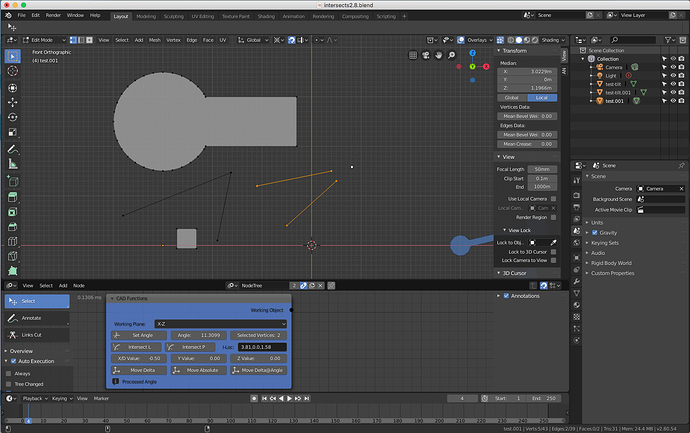

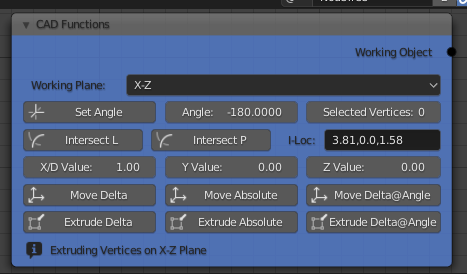

As a design engineer I can see many things I would like in Blender to make drawing mechanical parts better (CAD Functions), along with the suggestions already made here, might I also add:

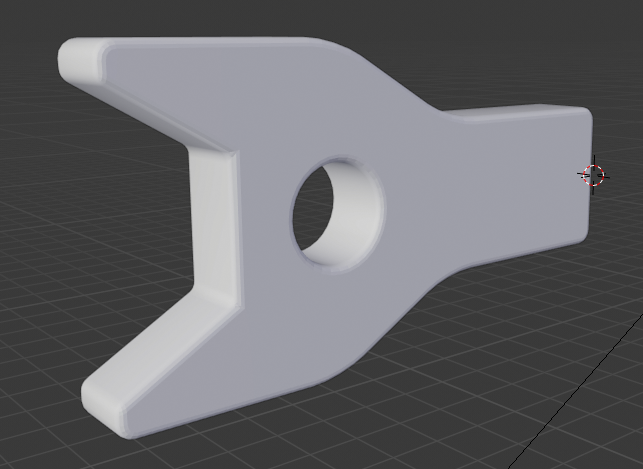

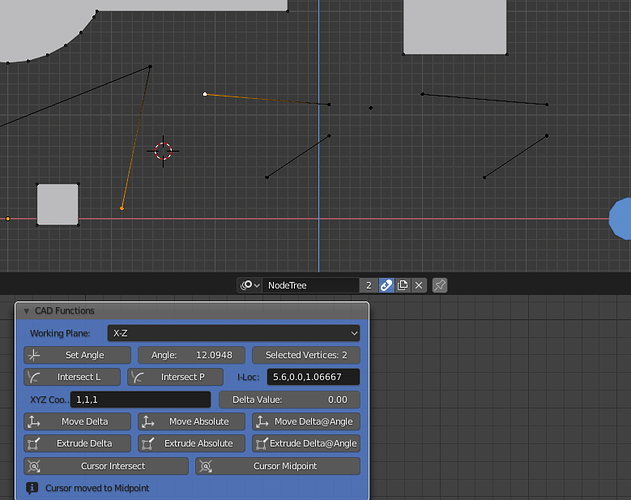

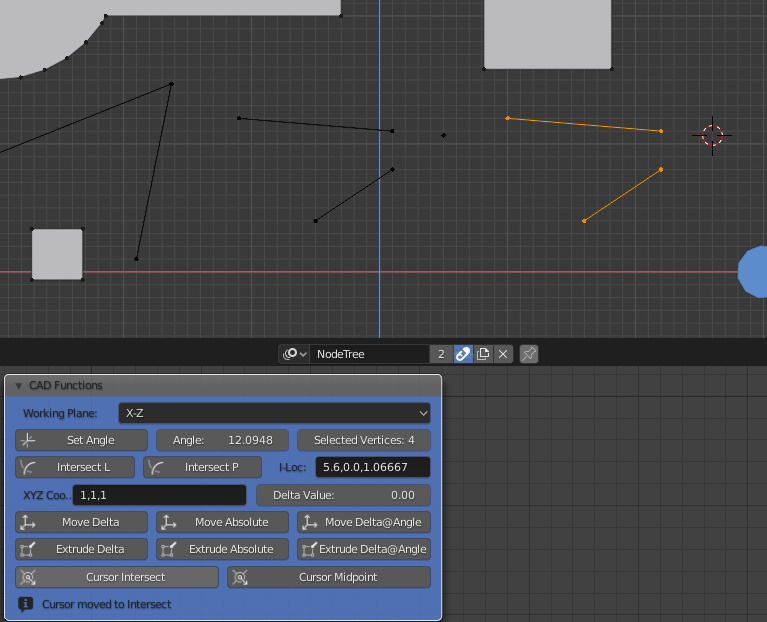

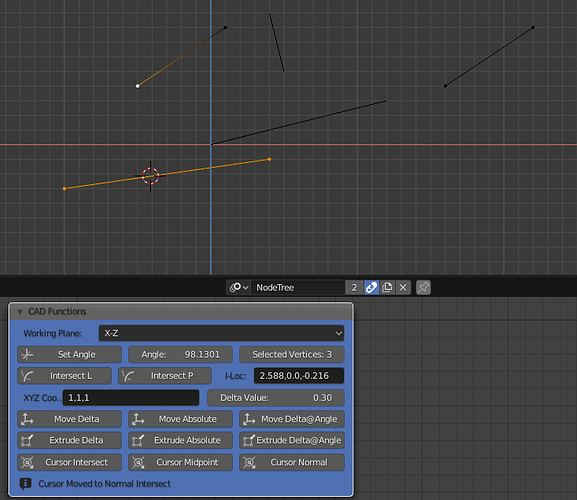

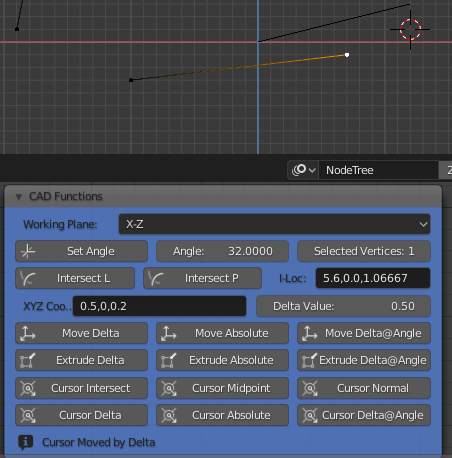

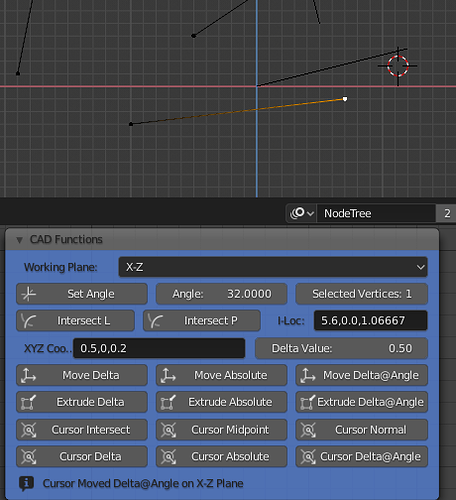

- Ability to extrude a vertex, or series of vertices, by a delta coordinate from its position, or by a delta length and rotational angle relative to the view plane.

So a workflow like: select vertex, extrude, key DC 1.2,1.4,0 extrudes the vertex 1.2 in X, 1.4 in Y and 0 in Z. Or key DR 1.3,45 extrudes the vertex 1.3 at an angle of 45 degrees relative to view positive X (3 O’clock).

- Ability to use a “Tentative Snap” (T-snap) to an existing vertex.

So a workflow like: select a vertex, T-snap any existing vertex, accept this location, or key a delta offset like DC 1.2,1.4,0 or DR 1.3,45. This gives us the ability to use another vertex on the model as a starting point for a delta offset.

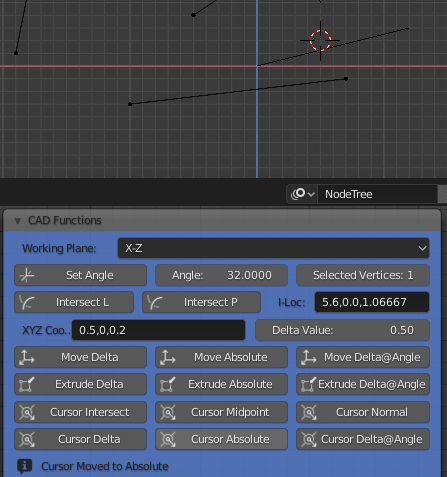

- Ability to use an absolute 3 axis location.

So a workflow like: select a vertex, extrude, key XY = 1.4,2.6,3.0 this extrudes the vertex to the absolute coordinate given.

- Ability to input an absolute, or T-snap + delta input to place a new single vertex.

So a workflow like: add vertex, key XY 1.4,2.6,3.0 or T-Snap existing vertex and key DC 1.2,1.4,0, or key DR 1.3,45.

- Ability to add primitive shapes at absolute, or T-snap + delta input.

So a workflow like: add rectangle, key XY 0,0,0, key DC 2,1.3 creates a rectangle with the bottom left vertex at 0,0,0 and the top right vertex at 2.1,1.3,0.

It is assumed that 0 input need not be added, so DC ,3 means delta 3 in Y axis, for example. XY 0 means all inputs 0, etc.

- Close a polygon after so many vertices have been added.

So a workflow like; add vertex, extrude, key DC 1.2,0,0 key DC 0,1.4, etc, etc, some command to close the polygon, i.e. join the last vertex to the first one.

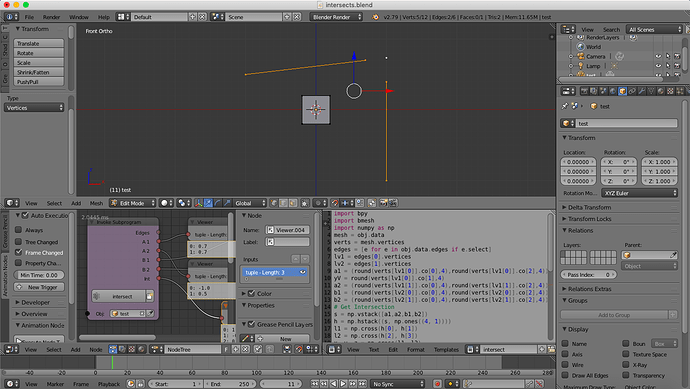

The ability to create a single vertex and then extrude it around a coordinate defined path then close it is a fundamental requirement for CAD. The ability to tentatively snap a vertex and use this to place a new vertex, or extrude an existing one will greatly improve the workflow and reduce the time taken to create geometry.

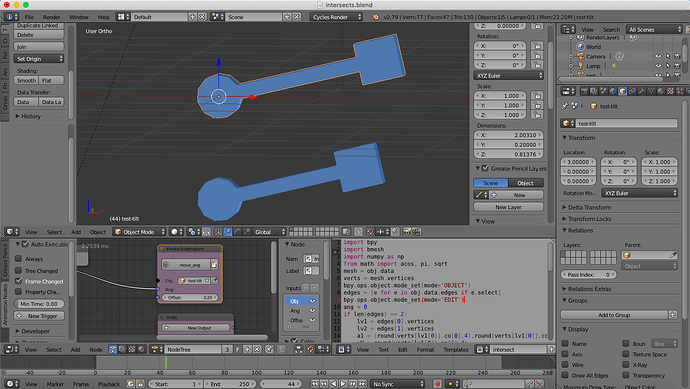

- The ability to create “parts” of geometry in a library. I know you can do this by creating objects in a blend file and then appending them, but the workflow is not CAD friendly.

So a workflow like; create a geometry - a bracket for example, that will be used extensively in the model, or in many models. Add this to a “Parts” library so it can be easily recalled later (think Pose Libraries…). Each part has an origin and is placed with the origin at the cursor location, or using a T-snap and delta input.

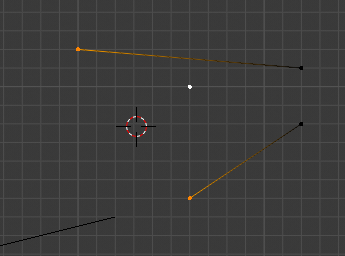

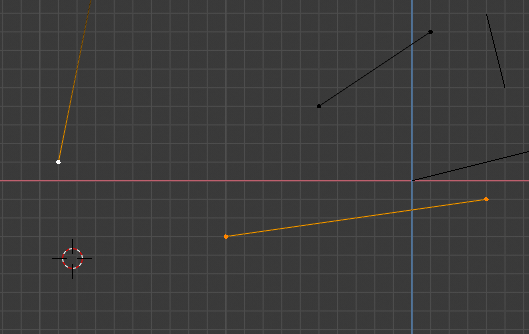

- Ability to extrude a vertex along the path defined by itself and the previous vertex, or to extend the vertex along the same path without adding a new one. So if you have an edge from 0,0 to 3.4,5.3, extrude this to make a straight line of three vertices, or move the end vertex in line with the path defined by the two vertices by a set distance, i.e. make the line a bit longer without changing the angle of the line.

Imaging here you have made a hydraulic cylinder at an angle of 23.45345 degrees to the horizontal and you want to make it 2cm longer, without that operation taking you half a day…

- Ability to rotate the view by a set amount, like say 46 degrees about its normal axis for example, or 37 degrees about the global X axis.

As a design engineer working on a drawing board, I would start with construction lines and work from there, I don’t see the need for this in Blender, if T-snap & delta inputs can be achieved. Things must line up in technical drawing, so T-snap is a must. In all the products I have worked with, Intergraph IGDS was the easiest to use to rapidly create precise geometry. It had a “T” button on the cursor and the ability to input 3 axis absolutes and delta offsets. It also had a Parts Library, although it was called a “Cells Library”.

I don’t see these additions as a large amount of work by the way, just some additional key-ins and the T-snap to make life such easier. The other function I used extensively in those days was “Copy Parallel” - this we have with the “Offset Edges” add-on, so this should be included as well. I also like the ability to select two vertices and join them with an edge, I am not sure if Blender can do this easily, I know we can select two unconnected edge strings and make a face of them, but this is not quite the same thing…

While I am on a flow here, could we also add the ability to create shapes within shapes as holes without having to add a least two edges from inside loop to outside loop, thus creating two Ngons that don’t have holes…

I think that basic, efficient draughting techniques have been lost in not only 3D modelling packages like Blender, but also many CAD packages, the old ways were not always the best, but they certainly had a lot of merit. Systems in the 1980’s had to be very efficient and fast to compete with a good draughtsman and had to run on computer systems that were toys (think VAX PDP 11’s) compared with today’s machines.

Let me know if anyone agrees with me, I am more than willing to expand these ideas, if they are thought relevant still, otherwise I can always enjoy my retirement!

Cheers, Clock.